Posted by Dmytro Dodenko

In the business world, there are truths that seem unshakable. One of them is: to earn more, you need to sell more of the product that brings the highest profit. It sounds logical. But what if this “truth” is a dangerous trap costing your company millions every month? This story is about how one simple shift in thinking can turn catastrophic losses into impressive profits.

Why Contribution Margin Is More Important Than Gross Profit

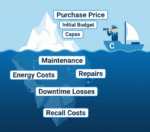

Before we dive into the paradox, it is important to understand the tools managers use for decision-making. There are two main approaches to cost accounting: absorption costing and variable costing.

Absorption costing, which is required for external financial reporting (GAAP/IFRS), includes all manufacturing costs — both variable (raw materials, direct labor) and fixed (factory rent, equipment depreciation) — in the product cost. This creates the Gross Profit metric. The problem is that with this approach, the unit cost changes depending on production volumes. If you produce more, you “spread” fixed costs over a larger number of units, and the cost of each supposedly decreases. This can create a dangerous illusion that producing for inventory increases profitability.

Variable costing, on the other hand, is a far superior tool for internal managerial decisions. It includes only those costs in the product cost that directly depend on production volume — variable costs. Fixed costs are treated as period costs and are written off completely, regardless of how much was produced or sold.

This approach gives us a much cleaner and more useful metric — Contribution Margin. This is the difference between the selling price and variable costs, showing how much money each unit sold generates to cover fixed costs and form net profit. Unlike gross profit, contribution margin is not distorted by changes in production volumes and gives a clear understanding of the economics of each product.

That is why smart managers use contribution margin for short-term decision-making (e.g., which product to produce). It is the right tool. But, as we will see now, even the right tool in the wrong context can lead to disaster.

The Contribution Margin Trap: A Steel Mill Case Study

Let’s examine a real-world dilemma. A steel mill produces thin-sheet galvanized steel. There are two main production sections: the Rolling Mill and the Galvanizing Line.

Raw material (1.2mm thick black sheet metal) is processed at the Rolling Mill into thinner sheets of two types: 0.8mm and 0.4mm. Then, a zinc coating is applied at the Galvanizing Line.

The sequence of operations is identical for both products. However, reducing metal from 1.2mm to 0.8mm requires one pass, while reducing it to 0.4mm requires two passes.

Galvanizing occurs at a constant speed per square meter of surface area. However, 1 square meter of 0.8mm steel weighs twice as much as 1 square meter of 0.4mm steel. Therefore, calculated per ton, galvanizing 0.8mm metal is twice as fast as 0.4mm metal.

Data for each product is presented in the table:

| Metric | Rolled Steel 0.4mm | Rolled Steel 0.8mm |

| Monthly Demand, tons | 5,000 | 5,000 |

| Selling Price, UAH/t | 21,708 | 20,083 |

| Variable Costs, UAH/t | 19,738 | 18,649 |

| Contribution Margin, UAH/t | 1,970 | 1,434 |

| Rolling Time (1 ton), min | 10 | 5 |

| Galvanizing Time (1 ton), min | 8 | 4 |

The operating time for each production section is 7 days a week, 24 hours a day, totaling 43,200 minutes per month.

We cannot produce everything the market is willing to buy (10,000 tons total demand), so we must decide exactly what to produce and sell. The throughput capacity of the Rolling Mill is lower than that of the Galvanizing Line. This means the Rolling Mill is our constraint (bottleneck).

To maximize profit, we need to know which product is more profitable and produce it to meet market demand. If there is time left on the Rolling Mill, we will produce the second product.

The Decision Management, armed with standard managerial accounting knowledge, decides to bet on the product with the higher Contribution Margin per ton. Looking at the table, 0.4mm steel yields 1,970 UAH vs. 1,434 UAH for 0.8mm. The choice seems obvious.

The Financial Result In 43,200 minutes, the plant can produce 4,320 tons of this “most profitable” product (43,200 min / 10 min/t).

Let’s look at the numbers:

- Total Contribution Margin: 4,320 tons × 1,970 UAH/t = 8,510,400 UAH

- Operating Expenses (Fixed Costs): 9,000,000 UAH

- Net Result: -489,600 UAH (Loss)

Unfortunately, this managerial decision leads to a monthly loss of half a million hryvnias. The company, while trying to maximize profit, is confidently marching toward bankruptcy.

How is this possible? The problem isn’t the math — it’s the question we asked.

A Paradigm Shift: Introducing the Theory of Constraints

Israeli physicist and business guru Eliyahu Goldratt, in his legendary business novel The Goal, offered a revolutionary view on management. His Theory of Constraints (TOC) states that the performance of any system (whether a factory or a hospital) is determined by its weakest link — the constraint. Any effort to improve non-constraints is a waste of time and resources.

Imagine a group of hikers on a trail. The speed of the entire group is determined not by the fastest athlete, but by the slowest hiker named Herbie. There is no point in rushing those in front — they will just have to wait. The only way to speed up the whole group is to help Herbie: lighten his backpack and put him at the front to set the pace for everyone.

Returning to our plant, the constraint, or “Herbie,” is the Rolling Mill. The traditional approach asks the wrong question: “Which product yields more profit per ton?” TOC forces us to ask: “Which product generates more profit per unit of time of our scarcest resource — a minute of Rolling Mill time?”

Let’s recalculate:

- Throughput (0.4mm Steel): 1,970 (UAH/t) / 10 (min/t) = 197 UAH per minute

- Throughput (0.8mm Steel): 1,434 (UAH/t) / 5 (min/t) = 286.8 UAH per minute

The Moment of Truth. The 0.8mm steel, which seemed “less profitable,” actually generates money for the company almost 46% faster. Every minute spent on it is far more valuable.

A 2.2 Million Hryvnia Turnaround

Armed with this new understanding, we completely change the production plan. Now the priority is 0.8mm steel.

- Виробити весь ринковий попит на пріоритетний продукт: 5000 тонн сталі товщиною 0,8 мм. Це займає 5000 т × 5 хв/т = 25 000 хвилин часу прокатного стану.

- Use the remaining time: We have 43,200 – 25,000 = 18,200 minutes left.

- Produce the second product: In this time, we can produce 18,200 (min) / 10 (min/t) = 1,820 tons of 0.4mm steel.

Now, let’s look at the financial result of the new plan:

- Total Contribution Margin: (1,820 t × 1,970 UAH/t) + (5,000 t × 1,434 UAH/t) = 10,755,400 UAH

- Operating Expenses: 9,000,000 UAH

- Net Result: +1,755,400 UAH

Simply by changing the question we ask, the company went from a loss of nearly half a million to a profit of almost 1.76 million. A total financial turnaround of over 2.2 million hryvnias per month. Without any investment, without changing equipment or staff.

Find Your Constraint

The Theory of Constraints offers a simple and powerful path to systems thinking through the Five Focusing Steps:

1. Identify the system’s constraint. Which element of the system is holding you back right now? What currently dictates its maximum throughput? Is it an internal factor (a resource or policy) or an external one (the market, supply chain, a supplier, or again, a policy)? If the identified constraint can be eliminated without significant cost, do it immediately and return to step one. If not, proceed to step two.

If you don’t know your constraint, you are not managing the system.

2. Exploit the constraint. How can you squeeze the maximum out of the constraining element without substantial additional costs, thereby reducing its negative impact on the entire system? For example, if the system’s constraint is market demand (sales volume), you need to intensify sales efforts and try to increase turnover. If the constraint is an internal resource, you must utilize this resource as efficiently as possible to prevent downtime. Do not load it with “junk” work (defective parts or low-margin products).

3. Subordinate everything else to the above decision. Once the constraint is found (Step 1) and the decision on how to maximize it is made (Step 2), we align the entire system to support this decision. Non-constraint resources must work at the speed of the constraint—neither faster nor slower. If they work faster, you will simply create mountains of Work-In-Process (WIP) and freeze cash, but you won’t sell more. Then, analyze the results: is this constraint still holding back the entire system? If not, we have eliminated it and move to Step 5. If yes, the constraint still exists, and we proceed to Step 4.

4. Elevate the constraint. If Steps 2 and 3 are insufficient to eliminate the constraint, you need to evaluate ways to “expand” it. “Elevating” means increasing the resource’s capacity. For an internal resource, this means increasing its productive time or its throughput. Standard methods include purchasing additional equipment, expanding staff, adding overtime, or introducing extra shifts to reach 24/7 operation. As a result, the constraint will be broken, and another element of the system will become the new constraint.

Remember: Investment anywhere other than the constraint is money down the drain.

5. Go back to step 1, but beware of inertia. If the constraint is broken during Steps 3 or 4, we must return to Step 1 and start the cycle again. Our task is to identify the next element holding back the system. The warning about inertia reminds us not to become complacent or stop at what has been achieved: the cycle never ends. We must seek and eliminate constraints, constantly remembering that due to interdependencies and variability, every change we make impacts the constraints we dealt with previously. You may need to revisit them and make adjustments.

The process of improvement is never-ending.

Conclusion

Your constraint is not a problem; it is your lever of control. Stop trying to improve “everything at once.” Find the single point holding your company back and focus your energy there. That is where your next breakthrough in profitability is hidden.

Pingback: Toxic KPIs: How Misguided Motivation Kills Your Business | Financial management